Electrodes used in argon arc welding and resistance welding

Introduction of electrodes used in argon arc welding and resistance welding

Tungsten has a high melting point (3683℃±20℃), strong electron emission ability, high elastic modulus and low vapor pressure, therefore, it has been used as a thermal electron emission material since long ago. The emission efficiency of pure metal tungsten electrode is very low and it will recrystal at a high temperature to form equiaxed grain structure to make the tungsten wire droop and break. To overcome the disadvantages above and adapt to the development of new technology and craftsmanship of the modern industry, material scientists from various countries are devoting themselves to the research and development of various kinds of new electrode materials. With the tungsten as a base, adding some rare earth oxide that has a low electronic work function will raise the temperature for recrystallization and activate the electron emission as well. Rare earth metal oxide has an excellent thermal electron emission ability and rare earth and tungsten electrode material has been developed to replace the traditional radioactive thorium and tungsten electrode material. Several reparations and research results of rare-earth tungsten electrode material and the relevant application of electrode materials have been introduced in this article, and the prospect of the tungsten electrode broad application also has been described in order to provide the reference for China's rare-earth tungsten electrode material research and application. The property of tungsten makes it a very suitable electrode material for TIG welding and other similar work. Addition of rare earth oxide into the metal tungsten stimulates the electronic work function of it, which improves the welding performance of the tungsten electrode: the electrode arc starting performance is better, the stability of the arc column better and electrode erosion rate lower. Usually the additives of rare earth are cerium oxide, lanthanum oxide, zirconium oxide, yttrium oxide and thorium oxide, etc.

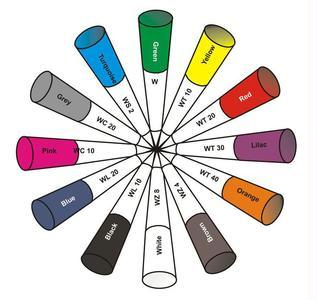

The tungsten electrode is made with a material that has a high melting point, corrosion resistance, high density and a good thermal and electric conductivity. The tungsten electrode is widely used in welding for its properties. Grinding or polishing of tungsten electrode and black bar. Their final color is not the same, which can be used to tell the difference. It is more important that the difference of final color of the electrodes means different content of tungsten in the electrodes. Correct selection of tungsten electrodes for welding will make welding easier and the more important is to get a better quality of welding. Some important factors such as power source (an inverter or a transformer), material to be welded (steel, aluminum or SS) and the thickness and the type of the material shall be considered in the correct selection of tungsten electrodes.

Tungsten Electrode

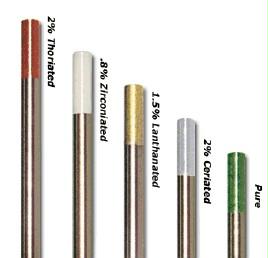

Tungsten electrode used in TIG welding is a tungsten alloy bar which is made with addition of about 0.3 to 5% rare earth elements that are cerium, thorium, lanthanum, yttrium and zirconium, etc. into the tungsten base body via method of powder metallurgy and pressure processing. The diameter of the electrode is from 0.25 to 6.4mm, the standard length from 75 to 600mm and the diameters of most commonly used specifications are 1.0mm, 1.6mm, 2.4mm and 3.2mm. The shape of electrode end is an important factor to the TIG. When DCSP is used, the electrode end shall be ground to be pointed and the angle of the point will change with the range of application, diameter of the electrode and the current used in welding. The narrow joint requires smaller point angle. When a very thin material is to be welded, low current is required and the smallest electrode with needle shape is required to make the welding to stabilize the arc. The appropriate grounding electrode can ensure easy arc starting, good arc stability and proper bead width. When the AC power supply is used in welding, it is not necessary to grind the end of electrode. Because when appropriate welding current is used, the electrode end will form a half ball shape which will turn into a bulb shape if welding current is increased, and is likely to melt and contaminate the molten metal.。

With development and wide application of inert gas protection welding with tungsten electrodes, the research on tungsten electrode is also more and more profound. The thorium and tungsten electrodes had been used in a plasma arc welding, cutting and non melting electrode argon arc welding. The thorium has a radioactive impact (the radiation dose up to 3.60 x 105 Curie/kg) which will harm the human health and pollute the environment, therefore cerium and tungsten electrodes with content of 2 to 4% of cerium oxide are used instead of thorium and tungsten electrode. When DCSP argon arc welding is used, the cerium tungsten electrode is easy for arc starting, with less burning loss of electrode and allowable welding current density is greater than that of the thoriated tungsten; and in AC argon arc welding, the burning loss of cerium and tungsten electrode is greater than that of thorium and tungsten electrode and welding current allowable range used by cerium and tungsten electrode is less than that of thorium and tungsten electrode。Thorium and tungsten electrode has the advantages of simple operation, even under the current overload the operation can also be well performed. There are still a lot of people who use this material, which is regarded as a part of high quality welding. Even so, people gradually turn to other types of tungsten electrode, such as cerium tungsten and lanthanum tungsten. Some welders don’t want to be close to the thorium and tungsten electrode since the thorium oxide in it will generate a trace of radiation。——————————————————————————————————————————————Recommended products: 1. cerium and tungsten electrode 2. thorium and tungsten electrode 3. lanthanum and tungsten electrode 4. yttrium and tungsten electrode5. zirconium and tungsten electrode 6. pure tungsten electrode and7. composite multiple electrode——————————————————————————————————————————————Call us if you have any requirement:

BEIJING TOPONE TUNGSTEN& MOLYBDENUM TECHNOLOGY CO., LTDContact: Li Shuqing

Mobile:13501237966130Tel: 010-51668956

Fax: 010-51668959

Please scan two-dimensional code on the right side to save the contact

ApplicationsContact Us

WeChat public platform Tel:+086-010-51668956 Fax:+086-010-51668959 Sales Address:Room 113, Tower M, No. 99, Changping Road (Luzhuang Bridge West), Shahe Town, Changping District, Beijing Factory Address:Tianjin jixian state town industrial park Email:sale@bjtpwm.com |

The property of tungsten makes it a very suitable electrode material for TIG welding and other similar work. Addition of rare earth oxide into the metal tungsten stimulates the electronic work function of it, which improves the welding performance of the tungsten electrode: the electrode arc starting performance is better, the stability of the arc column better and electrode erosion rate lower |