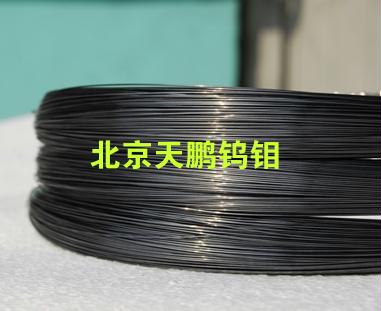

Spray-painted Molybdenum Wire

Details

The molybdenum wire spray-on coating has perfect wearability and very high interlayer peeling strength under the condition of heavy load; therefore, it is considered as essential material for metal hot spraying technology, and is extensively applied in the surface hot spraying of automotive components and parts like piston ring, synchronizer ring, and gearbox. The spray-painted molybdenum wire may also be used to repair worn-out machinery parts (such as bearing, bearing bush, and crankshaft) in overlay welding mode. Furthermore, spray-painted molybdenum wire may also be used as intermediate transition coating.

Chemical Composition

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

The Maximum of Impurity Contents

|

|

|

|

Brand

|

|

Mo Content (%)

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Al

|

Si

|

C/Fe/Ti

|

Ni/O/Cr

|

|

Ca/Mg/Na

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Mo1

|

|

≥99.95

|

|

0.002

|

0.003

|

0.005

|

|

0.003

|

|

0.002

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Products Description

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Diameter

|

|

Surface Color

|

|

Per Weight

|

|

|

Package

|

|

|

|

|

Ф3.17

|

|

|

|

|

|

5~30

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Black

|

|

|

|

|

|

Reeling

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ф2.31

|

|

|

|

|

|

5~30

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Black

|

|

|

|

|

|

Reeling

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ф1.60

|

|

|

|

|

5~30

|

|

Reeling or wire

|

|

|

|

|

|

Black

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

coiling

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Ф1.45

|

|

|

|

|

5~30

|

|

Reeling or wire

|

|

|

|

|

|

Black

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

coiling

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Indicated: others to be customized

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|